YASA, now part of Mercedes-Benz, is set to transform axial-flux motor technology with plans to produce 25,000 units next year—a remarkable leap from just 1,000 units five years ago. Operating from a new state-of-the-art facility in Yanton, this British company leads the charge in innovative electric motor design.

What Sets Axial-Flux Motors Apart?

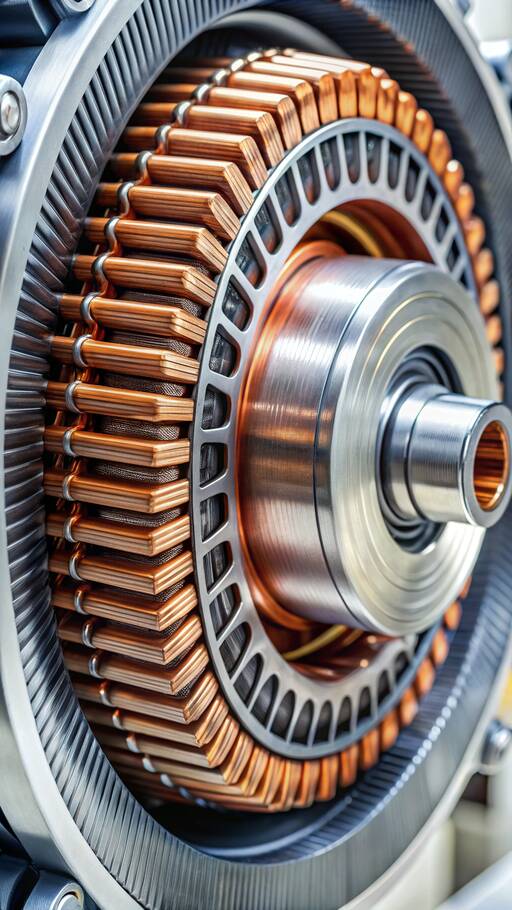

Design Innovation

- Features a dual-rotor setup flanking the stator.

- Eliminates the need for a stator yoke, making the design more streamlined.

Advantages

-

Weight & Size: 25 kg lighter and 45% smaller than radial-flux motors.

-

Power Density: Up to four times more power-dense.

-

Design Flexibility: Easily integrated between the transmission and engine or in tight spaces.

Real-World Applications

Hybrid Integration

-

Ferrari SF90: Maintains ideal weight distribution by avoiding an increased crank height.

Manufacturer Flexibility

-

Lamborghini: Uses motors permanently attached for torque vectoring.

-

Ferrari: Positions the motor behind the engine, allowing for rear-drive only.

Future Outlook

Continuous Innovation

-

Annual Improvements: Achieved 25% enhancements over the past 15 years.

-

Manufacturing Advancements: Introduces new techniques to remain competitive.

Forward-Thinking Philosophy

"We can't afford complacency. We'll continue to disrupt our technology, aiming to look back in a decade and see today's work as obsolete," says Woolmer, the originator of YASA.

Summary

YASA's axial-flux motors are reshaping how automotive manufacturers approach performance and design. With lighter, more power-dense motors, the industry gains flexibility and efficiency, ensuring YASA remains a leader in innovative electric motor technology.