The Case Against In-Wheel Motors

Placing motors directly in the wheels can significantly impact ride quality and handling dynamics due to the added unsprung weight. Over the years, companies like Lightyear and Lordstown Motors have experimented with wheel-hub motors, but they encountered financial challenges. However, recent advancements have brought the wheel-hub motor back into the spotlight, exemplified by BMW's $30 million investment in hub motor provider DeepDrive.

The Orbis Wheel Concept

In 2018, Orbis Wheels introduced a hub motor solution to the market. During a test with a Honda Civic Type R, Orbis showcased its potential by improving the 0–60 mph time by 1.7 seconds using two 50-hp motors for the rear wheels. Despite initial concerns about noise and durability, continuous improvements have made these motors appealing to various automotive manufacturers.

Breakthrough Orbis Innovations

1. Modular Tunable Axial Flux Motor

Orbis utilizes pancake-style, axial-flux motors where a rotor is sandwiched between stators, allowing for customization. These motors can range in power from 184 to 738 lb-ft, depending on the content of rare-earth or ferrite magnets. This flexibility reduces material costs and enhances performance efficiency at higher speeds.

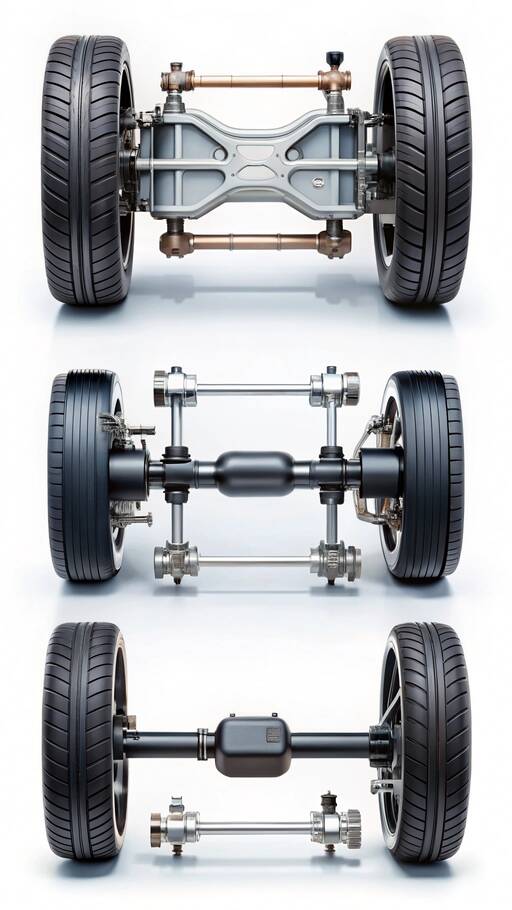

2. Planetary Torque Multiplication

Orbis incorporates simple planetary gear systems at the wheel hub for torque multiplication, achieving ratios from 2.50:1 to 5.25:1. This innovation enables more effective torque delivery compared to traditional direct-drive systems.

Key Variables for Success

Orbis aims to offer OEMs (Original Equipment Manufacturers) cost-effective plug-in hybrid electric vehicle (PHEV) solutions without relying exclusively on rare-earth elements. This approach maintains adaptable performance through customizable gear and magnet configurations.

Optimizing Performance: Balance with Unsprung Mass

Among a wide range of hub motor solutions, Orbis demonstrates an unparalleled torque-to-weight ratio. By adding only about 5 pounds per wheel in the vehicle's production version, significant improvements are achieved compared to conventional EVs. These efficiencies allow automakers to consider using heavier, less costly battery chemistries without compromising overall performance.

Ensuring Durability

Built as an integral part of the suspension, the motor housing is highly rigid and weather-sealed to IP67 standards. Existing vehicle components are preserved, enhancing the system's strength and reliability.

Unleashing Aftermarket Potential

Orbis is set to revolutionize the aftermarket scene, particularly among delivery vehicle fleets and the tuner community, with a certified kit for quick, three-hour installation that offers substantial fuel savings. An OEM platform paves the way for productionizing all-wheel-drive retrofits.

Surprising Applications

Orbis has expanded its applications to refrigerated semi-trailers by integrating air-cooled motors that recapture energy to power electric alternatives, effectively halving the necessary battery sizes. This technology is now helping to reduce electrification costs in the trucking industry.

In Summary

The resurgence of wheel-hub motors, driven by Orbis' innovations and significant industry investments, heralds a new era for electric vehicles by unlocking potential cost savings, performance improvements, and environmental benefits.